Ninja H2 Video XIX: High Quality Materials + Video

The Kawasaki Ninja H2 teaser videos aren’t showing any signs of letting up, and today, Kawasaki has released video number 19 in the series. This time, highlighting the high quality materials used in the H2. As you watch the video, consider these notes from MO’s Editor in Chief, Kevin Duke:

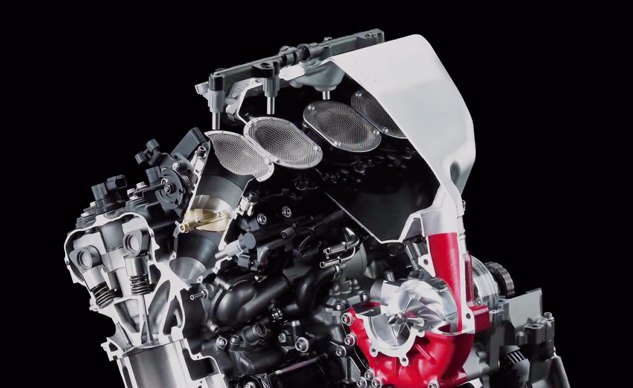

- The supercharger impeller is machined from billet aluminum. This is a costly process for a volume OEM.

- Inconel exhaust valves. This is an exotic metal that can resist extreme temps better than titanium.

- Note the aluminum airbox, rather than a nylon or plastic type seen on most production bikes. It’s able to handle the greater-than-atmospheric pressures from the supercharger.

- Regarding the steel-trellis frame: This is the first time I’ve seen the whole thing. Looks far more robust than seen with bodywork. Intricate steel tubes used instead of aluminum beams to more easily accommodate the powerplant and its attendant plumbing.

- Knurled section on rear wheel to prevent the tire slipping on the rim under extreme acceleration.

While those are the bits you can see in the video, KD saw the H2 in person at the AIMExpo recently, and came back with these interesting tidbits:

Kawasaki’s Croft Long told me Kawi tried to contract existing supercharger companies to build the H2’s unit, but they all apparently said that what they were looking for couldn’t be done, even Eaton, which supplies the superchargers for Jet Skis. So Kawi did this on their own. When I asked Croft what details of the H2 haven’t received enough attention, he noted the extreme efficiency of the supercharger but wouldn’t elaborate further.

On that note, I asked Rob Muzzy what he thought while we looked at the engine cutaway, and he also was perplexed at how the heat created from pressurized inlet air could adequately be dissipated. So, there appears to be something special about Kawi’s supercharger design that has yet to be fully explained.

Troy's been riding motorcycles and writing about them since 2006, getting his start at Rider Magazine. From there, he moved to Sport Rider Magazine before finally landing at Motorcycle.com in 2011. A lifelong gearhead who didn't fully immerse himself in motorcycles until his teenage years, Troy's interests have always been in technology, performance, and going fast. Naturally, racing was the perfect avenue to combine all three. Troy has been racing nearly as long as he's been riding and has competed at the AMA national level. He's also won multiple club races throughout the country, culminating in a Utah Sport Bike Association championship in 2011. He has been invited as a guest instructor for the Yamaha Champions Riding School, and when he's not out riding, he's either wrenching on bikes or watching MotoGP.

More by Troy Siahaan

Comments

Join the conversation