BMW Made 3D-Printed Radiator Covers for 2018 International GS Trophy

Last week, BMW held its annual International GS Trophy competition, pitting teams of three all riding R1200GS Rallye bikes in various challenges while riding across Mongolia. South Africa came out on top, followed by the U.S. and France.

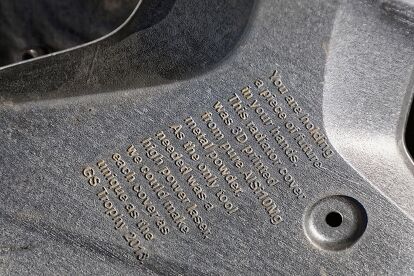

Along with the experience of a lifetime, the competitors got to take home personalized trophies, namely, individually customized 3D-printed radiator covers used on their bikes. Each of the 114 R1200GS Rallye bikes was equipped with radiator covers bearing the rider’s name, start number, and the GS Trophy logo, all produced through additive manufacturing.

BMW used powerful lasers to fuse aluminum powder to produce each radiator cover. Customizing each cover was simple, requiring just a slight tweak to the algorithm. An additional milling process was then used to produce the final finish.

Begin Press Release:

Individualized radiator covers for the participants of the BMW Motorrad International GS Trophy Central Asia 2018 – thanks to additive manufacturing

A generative design algorithm was used to individualize the radiator covers of the 114 BMW R 1200 GS Rallye bikes: the rider’s names and start numbers were added to the existing CAD data of the part. Subsequently, the radiator covers were printed by using additive manufacturing.

Experts of the BMW Group Additive Manufacturing Center have teamed up with BMW Motorrad to individualize the bikes of the Int. GS Trophy 2018. A generative design algorithm was used to individualize the radiator covers of the 114 BMW R 1200 GS Rallye bikes: the rider’s names and start numbers were added to the existing CAD data of the part. Subsequently, the radiator covers were printed by using additive manufacturing.

In the selective laser melting process aluminum powder is fused by powerful lasers. As no tools are required, every produced component can be different, thus making it the perfect choice for individualization. At the same time, the resulting parts are of a very high strength – perfect for rough conditions like the Int. GS Trophy which took place in Mongolia from June 3 till June 10 2018. An additional milling process was used to create greater contrast and surface quality of the design.

As a souvenir from the 2,350 km journey, the individualized radiator covers were handed over to the participants at the awards ceremony.

More by Press Release

Comments

Join the conversation